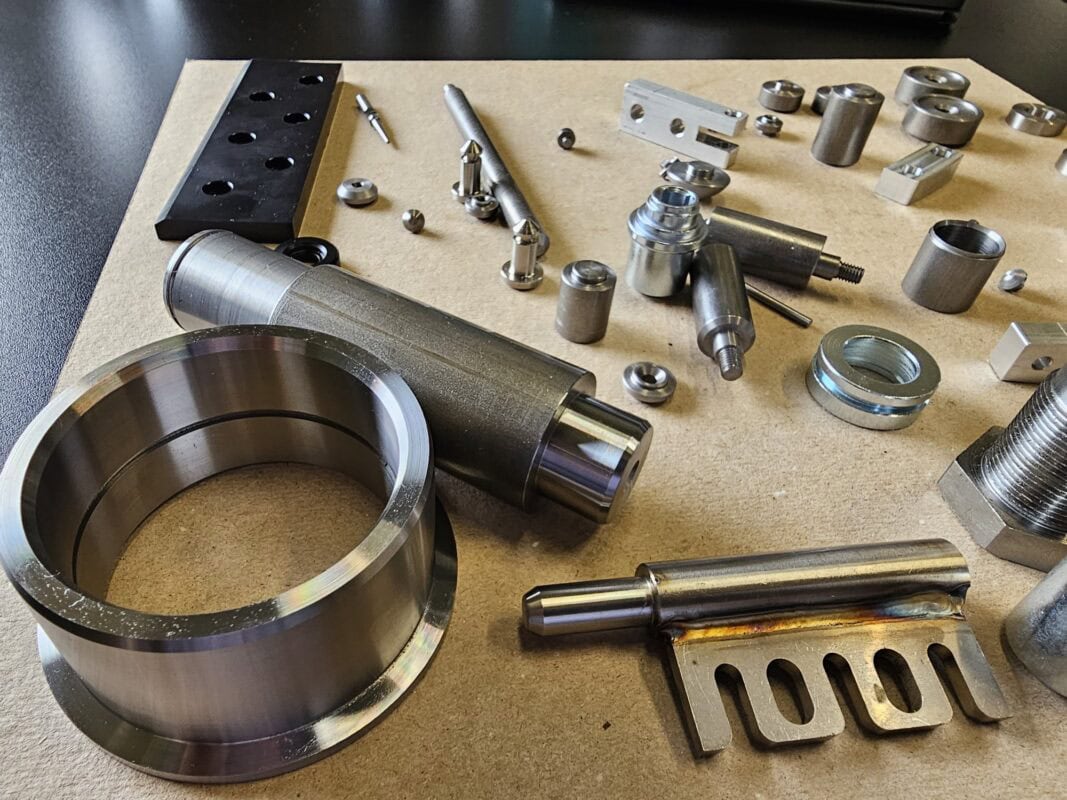

Your partner for CNC turning and milling

As a contract manufacturer for Machining and sheet metal working we combine modern CNC technology with practical experience from many industries:

-

CNC turning of rotationally symmetrical components

-

CNC milling of plates, blocks, profiles and sheet metal parts

-

Individual parts, small series and series production

-

Processing of steel, stainless steel, aluminium and other metals

-

Combination with laser cutting, bending, welding and surface treatment

So you get Complete metal parts and assemblies from a single source - with harmonised tolerances and consistently high quality. We not only offer you laser cutting, but also a high-quality Sheet metal processing for complex metal assemblies.

What does CNC turning mean?

During turning, the workpiece rotates while a cutting tool removes material. This process is particularly suitable for:

- Shafts, axles, bushes

- Sleeves, rings, flanges

- Turned parts with internal and external threads

- Conical and radius contours

CNC lathes enable tight tolerances, clean surfaces and economical machining - even with complex geometries and multiple clamping positions.

What does CNC milling mean?

During milling, the tool rotates and removes material from the clamped workpiece. Typical applications are

- Panel and block processing

- Milling of contours, grooves, pockets and chamfers

- Processing of 2D and 3D geometries

- Post-processing of sheet metal parts after laser cutting

CNC control enables complex shapes, drilling patterns and functional surfaces to be produced precisely and with repeat accuracy.

Turning and milling in combination with sheet metal processing

One major advantage is the combination of sheet metal processing and machining in a single production network:

- Laser-cut sheet metal parts can be milled, drilled or threaded

- Turned parts can be integrated directly into welded assemblies

- All parts come from a single source and are optimally matched to each other

- Fewer suppliers, one contact for sheet metal and machined parts

Materials for turning and milling

We process the usual materials used in industry and mechanical engineering:

- Steel (structural steel, free-cutting steel, heat-treated steel ...)

- Stainless steel for corrosion-resistant components

- Aluminium for lightweight constructions and housings

- Other metals after consultation

We will be happy to discuss with you which materials make the most sense for your project.

CNC milling process

We offer a variety of CNC milling processes so that we can machine your metal parts precisely and efficiently. These are tailored to different requirements and geometries.

CNC hobbing

CNC mould milling

CNC face milling

CNC profile milling

✅ CNC plunge milling

CNC face milling

- CNC face milling: For processing flat surfaces and precisely levelled surfaces that require a high degree of dimensional accuracy.

- CNC hobbing: Ideal for the production of gears and toothed components with maximum precision.

- CNC screw milling: Specially designed for machining helical profiles and threads.

- CNC profile milling: For processing complex profiles and contours according to your specific requirements.

- CNC mould milling: Enables the production of complex shapes and three-dimensional geometries.

- CNC plunge milling: Perfectly suited for plunging the milling tool into the material and machining hard-to-reach areas.

Typical components and applications

Our turned and milled parts are used in the following areas, among others:

- Mechanical and plant engineering

Shafts, flanges, bearing blocks, adapters, spacers, connecting elements - Conveying and handling technology

Rollers, axles, fastening elements, milled guide parts - Housing and switch cabinet construction

Milled mounting plates, spacers, mechanical housing components - Vehicle and commercial vehicle construction

Fastening elements, components for superstructures and frame constructions - Metal construction, special machines, devices

Individual parts and assemblies for testing and clamping devices

We will be happy to check your drawings and suggest a production-orientated, economical solution.

From the drawing to the ready-to-install turned or milled part

From the drawing to the ready-to-install turned or milled part

Our 5-step process for precise CNC manufacturing

Your enquiry

You send us your drawings or 3D models (STEP, DXF, DWG, PDF) with details:

- Material

- Quantity (individual parts, small series, series)

- Tolerances and functional surfaces

- Surface requirements

- Desired delivery date

- Delivery address in Germany or Austria

Technical testing and consulting

We check feasibility, clamping concept, tolerances and the combination with other manufacturing processes. If required, we can advise you on a production-orientated design.

Offer and scheduling

You receive a transparent quotation with unit prices, delivery times and options for series, call-off quantities or framework agreements.

CNC production

Production takes place on modern CNC lathes and milling machines. You benefit from:

Post-processing, assembly and dispatch

We can take over on request:

Ready for your turned or milled part project?

Contact us for expert advice and a precise quote for your CNC production

Quality in machining

We rely on reliable series production:

- Qualified specialists in programming and production

- Documented checks of dimensions and surfaces

- Defined inspection plans for series and repeat parts

- Clear processes from raw material to delivery

In this way, we ensure that your turned and milled parts reliably fulfil the required tolerances and functions.

Contract manufacturing turning and milling for Germany and Austria

We regularly supply companies in Germany and Austria and are familiar with the requirements of the industry.

Your advantages:

- Predictable delivery times and reliable logistics

- Flexible response to fluctuations in demand

- Framework agreements and warehousing for recurring parts possible

This means you have a partner who can provide reliable support for both individual projects and series.

Machinery for CNC milling and turning of metal parts

Our state-of-the-art machinery for metal CNC milling and turning offers precise, reliable and economical manufacturing solutions for a wide range of industrial sectors. With high-performance CNC milling centres, flexible lathes and state-of-the-art control technology, we are ideally equipped to manufacture complex metal components to a consistently high quality - from individual parts to series production.

HAAS VF-2SSYT-EU - CNC milling centre for precise metalworking

Highlights for maximum efficiency:

- 8,000 rpm spindle speed for fast processing

- 30-position tool changer for minimum non-productive time

- 500 × 700 mm table size for medium to large components

- 3-axis machining for precise contours and complex geometries

- Ideal for aluminium, steel, stainless steel and special materials

Nakamura-Tome SC-100X2 - High-performance turning centre

Machine advantages at a glance:

- 41 % higher processing speed compared to predecessor

- Simultaneous processing with superimposed control

- Travelling distances:

- X: 150 mm

- Y: ±40 mm

- Z: 400 mm

- Machining length up to 4,000 mm

- Counter spindle 6,000 rpm

Perfectly suited for:

- Shafts, bushes, flanges, precision turned parts

- Series production with short cycle times

- Complex geometries with high dimensional accuracy

Tornos Swiss DT-26 - Swiss-type automatic lathe for high-precision turned parts

Technical features:

- Spindle clearance 25 mm for slim and complex parts

- FANUC 31iB controller for precise programming

- 5 linear controlled axes & 2 C-axes

- 22 tool positions, 2 independent tool systems

- Reduced non-productive times thanks to simultaneous processing

Ideal applications:

- Precision components with tight tolerances

- Fittings, bolts, bushes, complex small series

- Long turned parts for mechanical engineering, automotive, electrical industry

FANUC ROBODRILL α-D28LiB5ADV Plus Y500 - High-speed machining centre

Performance overview:

- Travelling distances:

- X: 700 mm

- Y: 500 mm

- Z: 400 mm

- Table load capacity up to 400 kg

- 24,000 rpm high-speed spindle

- 28-position tool changer

- Especially suitable for larger components and EV components

Application examples:

- Large milled parts

- Sophisticated 3D contours

- Series production with high surface quality

Why our machinery is the optimal choice

- High repeat accuracy & process stability

- Flexible processing of small, medium and large series

- Precision machining for mechanical engineering, automotive, electromobility, medical technology

- Modern CNC technology for short delivery times and economical production

- Complete machining from a single source: CNC milling + CNC turning

Also discover our other services, such as Welding.