Your construction partner for sheet metal and metal constructions

As a manufacturing company with its own Construction we know both the requirements of mechanical engineering and the reality of the workshop. You benefit from:

-

Development and design of sheet metal parts, assemblies and metal constructions

-

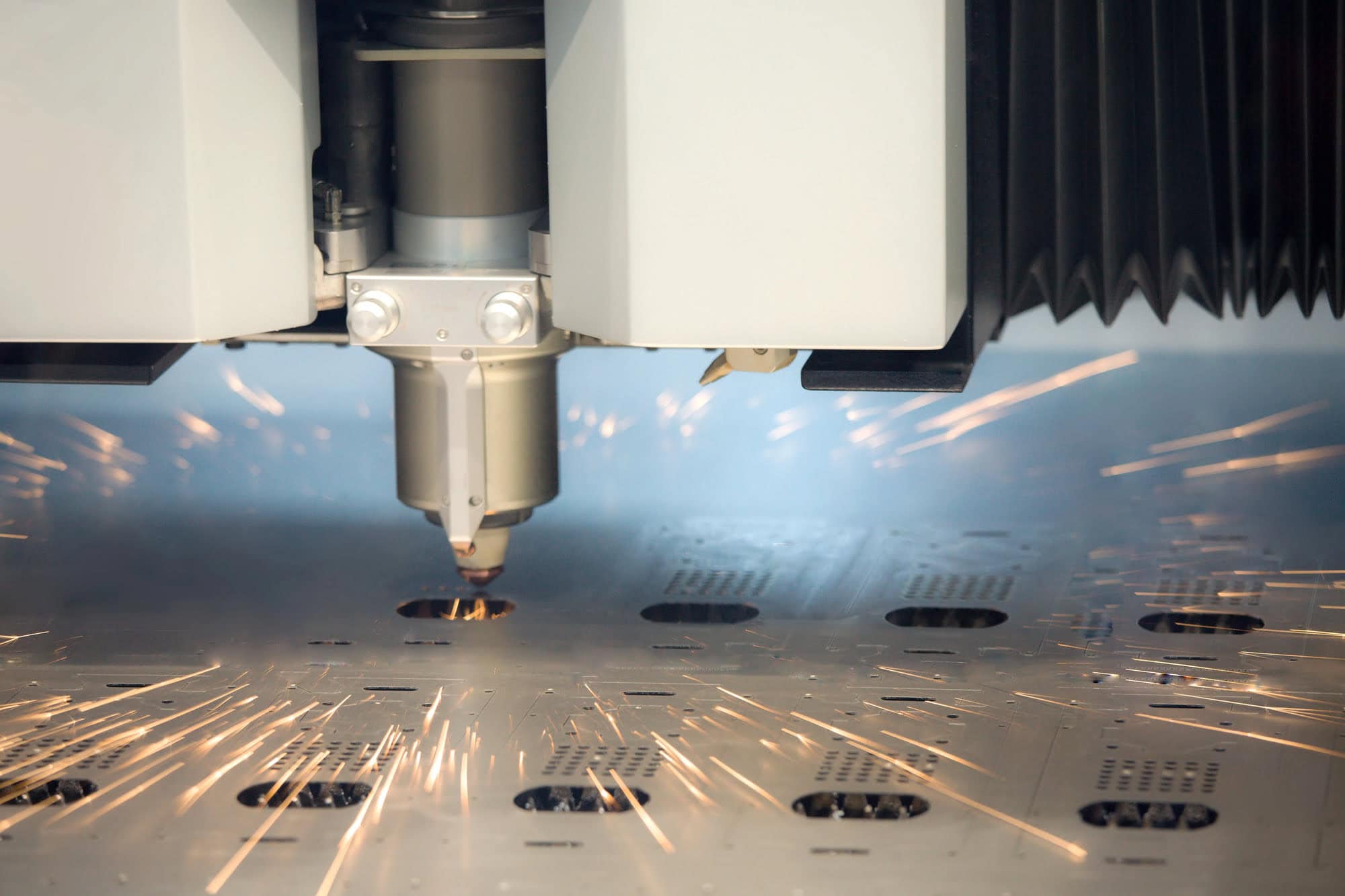

Production-orientated design for laser cutting, punching/nibbling, bending and welding

-

Adaptation and optimisation of existing drawings

-

constructive support for new developments and modifications

-

Close integration of design, work preparation and production

This results in solutions that not only work on paper, but can also be produced reliably, stably and economically in everyday use. In addition to laser cutting, we also offer you first-class Sheet metal processing for precise and accurately fitting metal components.

What we mean by development and design

Our services in the area of development and design include, depending on requirements:

- Development of concepts and component designs

- Design of sheet metal parts, racks, frames, housings and assemblies

- Creation or revision of 3D models and drawings

- Adaptation of existing designs to new requirements

- Production-oriented optimisation with regard to materials, processes and costs

We keep an eye on the entire process chain - from cutting, bending and welding to surface treatment and assembly.

Design for sheet metal and welded constructions

One focus is on the design of sheet metal and welded assemblies:

- Enclosures, switch cabinets, panelling

- Machine racks, frames and support structures

- Brackets, consoles, connecting parts

- Sheet metal assemblies with laser parts, folded parts and welded seams

We pay attention to:

- Sensible bending sequences and suitable bending radii

- Welding-compatible design (accessibility, seam lengths, distortion)

- Sufficient rigidity with minimum use of material

- Suitable tolerances for assembly, seals and functional parts

Co-engineering - cooperation with your design department

If you already have your own design, we can support you within the scope of co-engineering:

- Taking on subtasks (e.g. sheet metal construction within a larger machine)

- Revision of models with regard to production-orientated sheet metal processing

- Checking drawings for feasibility with our machinery

- Suggestions for cost reduction through material or design adjustments

This allows you to combine your product knowledge with our manufacturing experience and obtain a technically and economically convincing solution.

Production-orientated design - reduce costs, ensure quality

A good design is decisive for unit costs, production costs and process reliability. Through production-orientated design, we can:

- Reduce processing times

- Reduce material waste

- Optimise the number of individual parts and weld seams

- Standardise recurring parts

- Reduce assembly costs

The result is robust, practical designs that are stable to manufacture and reliable to install.

Data formats and technical documentation

We work with common CAD and exchange formats, e.g:

- 3D models (e.g. STEP*)

- 2D drawings (e.g. DXF, DWG, PDF)

*The specific formats can be customised to your system.

On request we create:

- Complete sets of drawings

- Parts lists and overviews

- Simplified data for ERP or PDM systems

Typical projects in development and construction

We work for customers from the following sectors, among others:

- Mechanical and plant engineering

- Conveying and storage technology

- Housing and switch cabinet construction

- Metal and steel construction

- Special machinery and fixture construction

Typical projects:

- New design of sheet metal housings and metal assemblies

- Revision of existing designs for more economical production

- Adaptations to new standards, safety requirements or installation situations

- Standardisation of component families and variants

Process - from your idea to the finished design

Professional development and design in 5 clearly structured steps

Task definition and clarification of requirements

At the beginning we clarify:

- Function and operating conditions

- Requirements for stability, appearance, safety, installation

- Interfaces to other components or systems

- Quantities, budget, schedule

Concept and first drafts

We develop initial solutions and concepts, which we coordinate with you before the detailed design begins.

Detailed design and elaboration

We create the complete construction including:

- 3D models

- Sheet metal unfoldings and flashings

- Welded assemblies

- Drawings with tolerances and production details

Prototypes and sample parts

On request, we can produce samples to check function, fit and assembly. The findings are incorporated directly into the optimisation process.

Readiness for series production and handover to production

After approval, we transfer all data to production. You receive:

Ready for your development project?

Contact us for professional advice and a customised quote for your design solution

Advantages of construction directly at the paver

You benefit from the close integration of design and production:

- short coordination channels

- Fast response to changes

- direct comparison with real production possibilities

- fewer interfaces and lower risk of errors

The result is a solution in which design and production work together optimally right from the start.

Development and design for customers in Germany and Austria

We support companies in Germany and Austria - from individual projects to series construction - and guide you through the entire development and production process. Discover our other services, such as Turning and milling.

Request a project in the area of development and construction now

Are you planning a new product, would you like to rework an assembly or do you need support in metal and sheet metal construction?

Send us your task, sketches or existing drawings - we will get back to you with a proposal for the procedure, the work involved and the schedule.