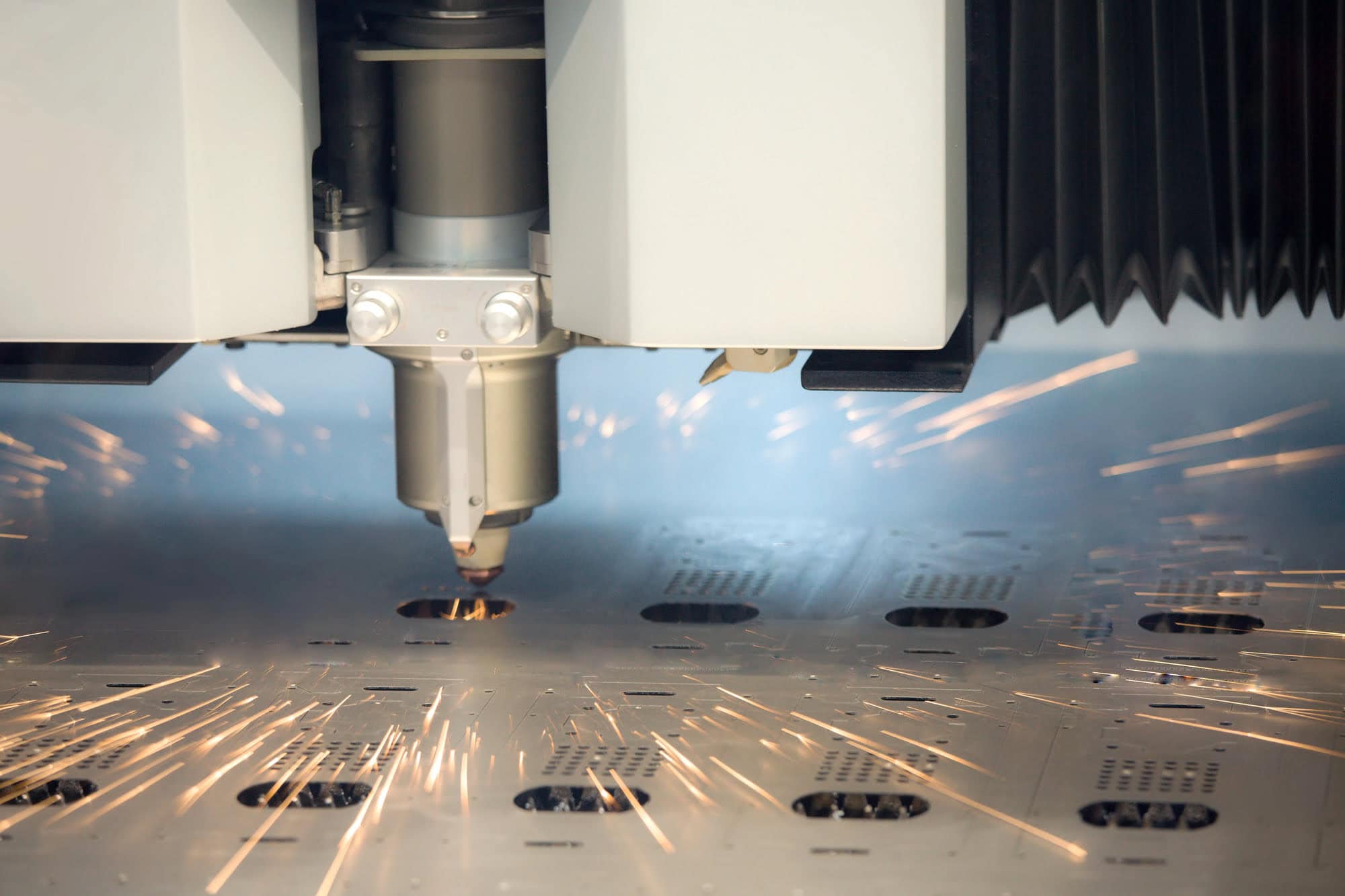

Your contract manufacturer for laser-cut metal parts

Whether simple contours or complex geometries - [company name] is your partner for laser cutting from sheet metal. We support you from enquiry to delivery:

-

Laser cutting of steel, stainless steel and aluminium

-

Production of prototypes, small series and large series

-

Components as individual parts or as complete assemblies

-

Short response times for quotation and delivery

-

Sheet metal processing, welding and powder coating from a single source

This saves you time in procurement, reduces interfaces and ensures that all metal parts are of a consistently harmonised quality. We also offer you comprehensive Sheet metal processing for precise sheet metal parts and complete assemblies.

Advantages of laser cutting metal

Today, laser cutting of metal is the central cutting process in modern sheet metal processing.

It combines high cutting speeds with excellent precision - without expensive punching tools.

Your advantages at a glance:

- High dimensional accuracy and repeatability

Precise contours, tight tolerances, ideal conditions for subsequent assembly or welding work. - Clean cut edges

Can often be used without reworking, depending on the material and sheet thickness. - Economical for small and large series

No mould construction necessary - changes to contours can be implemented quickly using CAD data. - Flexible geometries

Intricate cut-outs, engravings, slotted holes, slots, latching lugs, labelling and much more. - Perfect basis for further processing

Can be ideally combined with bending, milling, drilling, thread cutting and welding.

Which metals we laser

We laser metal sheets in all common qualities that are used in mechanical engineering, metal construction and plant engineering:

Steel (structural steel, thin sheet)

- Universally applicable for frames, brackets, consoles, reinforcements, sheet metal inserts, etc.

- Can be easily combined with subsequent surface treatment (e.g. powder coating, galvanising).

Stainless steel

- For components with high demands on appearance, corrosion protection and hygiene

- Areas of application: Food industry, medical technology, container construction, housings, visible parts

Aluminium

- Lightweight components with good corrosion protection

- Suitable for machine panelling, housings, vehicle construction, transport and conveyor technology

On request, we can also process other metals and special materials after consultation.

From the drawing to the finished laser cut

How the collaboration works - in 5 clear steps

Enquiry with drawing or sketch

You send us your enquiry with technical drawings (DXF, DWG, STEP, PDF) and details:

- Material and surface

- Sheet thickness

- Quantity (individual parts, series, repeat parts)

- Desired delivery date

- Delivery address (Germany or Austria)

Testing & consulting

Our design department checks the feasibility, optimises the geometries for cost-effective production if necessary and makes suggestions regarding material thicknesses or tolerances if required.

Offer & date

You receive a transparent quotation with prices, production time and delivery date. For scheduled projects, we coordinate production windows and delivery intervals with you.

Production on modern laser cutting systems

The sheets are cut on CNC-controlled laser cutting systems. Depending on requirements, we combine:

- Automated feeding with sheet metal storage systems

- Nesting optimisation for material savings

- Series production with high process reliability

Post-processing, assembly & dispatch

We can take over all further work steps on request:

Ready for your laser cutting project?

Contact us for professional advice and a precise quote for your laser cuts

Typical components and industries for metal laser cutting

- Mechanical and plant engineering

Machine parts, consoles, frames, panelling, covers - Housing and switch cabinet construction

Sheet metal housings, doors, mounting plates, ventilation openings, cut-outs - Conveyor technology & logistics

Conveyor belts, roller conveyors, racks, protective panelling - Vehicle and commercial vehicle construction

Brackets, beams, sheet metal parts for superstructures and interior fittings - Metal construction & construction industry

Stair parts, balustrade elements, façade and railing parts - Furniture, design & shopfitting

Visible parts, decorative elements, metal frames, displays

We customise materials, vertical integration and packaging to your requirements for every industry.

Quality in metal laser cutting

Quality is the basis of long-term co-operation. That is why we rely on:

- Trained specialists in programming, production and welding technology

- Continuous dimensional control during production

- Defined inspection plans for series and repeat parts

- documented processes and, if available, certifications (e.g. ISO, welding certificates)

This ensures that your metal laser parts have the same dimensions, surfaces and functions with every order.

Contract manufacturing for Germany, Austria, Switzerland and other countries

As a contract manufacturer for laser cutting metal, we regularly deliver to customers in Germany and Austria.

Dispatch is carried out reliably via established logistics partners, with fixed delivery dates or call-off orders if required. Discover our other services too, such as Punching/nibbling.

Your advantages:

- Short delivery times and predictable logistics

- High delivery reliability thanks to structured production planning

- Flexible response to peak demand and repeat orders